The 2025 US TPMS Regulations necessitate significant adjustments for businesses, directly impacting B-to-B sourcing strategies. Companies will require updated component specifications and enhanced testing protocols to ensure Regulatory Compliance. This may also lead to the development of new supplier relationships, ultimately helping to avoid penalties.

Key Takeaways

- New 2025 rules make TPMS sensors more accurate. They must work well in all weather. More types of cars need these sensors.

- Companies must find new suppliers. These suppliers must meet the new sensor rules. This helps avoid big fines and product recalls.

- Businesses should work with suppliers early. They need strong contracts. This helps make sure all parts follow the new rules.

Understanding the 2025 US TPMS Regulations: Key Updates

Specific Regulatory Shifts: What’s Changing in 2025?

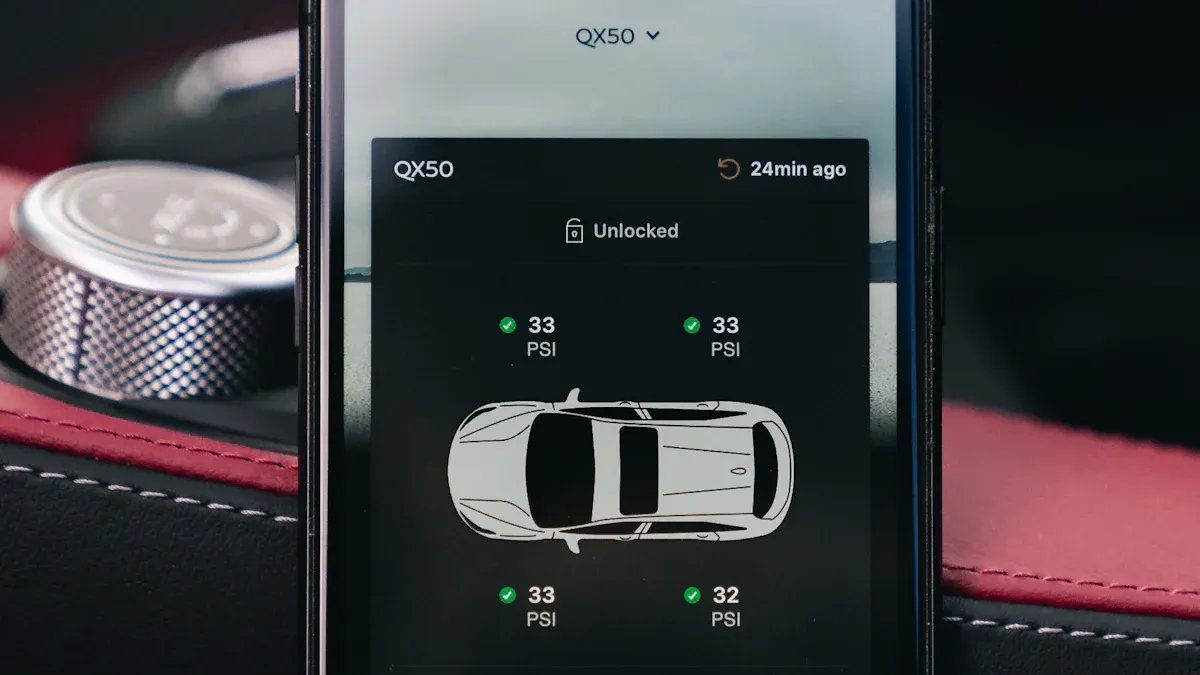

The 2025 US TPMS Regulations introduce significant changes, primarily focusing on enhanced vehicle safety and improved performance. These updated rules mandate stricter accuracy requirements for tire pressure readings, ensuring greater precision. They also demand improved system reliability across diverse environmental conditions, from extreme heat to cold. Manufacturers must ensure their TPMS units provide more consistent and precise data to drivers. The Regulations expand coverage to include additional vehicle categories, broadening their application across the automotive market. This means more vehicles will require compliant TPMS. Businesses must adapt their current product designs and testing protocols to meet these elevated technical specifications. Achieving Regulatory Compliance requires a comprehensive evaluation of existing TPMS components and their operational capabilities.

Compliance Deadlines and Penalties: The Cost of Non-Compliance

Businesses face critical deadlines for achieving full Regulatory Compliance with the 2025 TPMS standards. The National Highway Traffic Safety Administration (NHTSA) has set clear timelines for implementation, which companies must strictly observe. Missing these dates carries severe financial and operational risks. NHTSA can impose substantial penalties for non-compliant products, aiming to enforce adherence. These penalties include significant fines per vehicle sold or manufactured, which can quickly accumulate. Non-compliance also risks mandatory product recalls, severely damaging brand reputation and eroding consumer trust. Such actions lead to substantial financial losses and operational disruptions. Companies must prioritize timely adherence to these Regulations. Proactive measures ensure smooth transitions, prevent costly disruptions, and maintain market standing.

Impact on B-to-B Sourcing: Navigating New Regulatory Compliance Demands

Component Specifications: Adapting to New Technical Requirements

The 2025 US TPMS changes directly influence the technical specifications for critical components. Businesses must now source TPMS sensors offering enhanced accuracy and reliability. These new requirements extend to pressure sensors, temperature sensors, and integrated circuits. Manufacturers need components capable of precise measurements across a wider range of environmental conditions. This includes extreme temperatures and varying road dynamics. Furthermore, the expanded vehicle categories demand versatile TPMS solutions. These solutions must integrate seamlessly into diverse vehicle architectures. Sourcing teams must collaborate closely with engineering departments. They identify and procure components that meet these elevated performance benchmarks. This often involves evaluating new materials and advanced manufacturing processes from potential suppliers.

Supplier Qualification and Vetting: Ensuring Regulatory Adherence

The updated Regulations necessitate a more rigorous approach to supplier qualification. Companies must implement comprehensive vetting processes. These processes ensure their B-to-B partners can consistently deliver compliant TPMS components. This includes evaluating a supplier’s quality management systems and their adherence to international standards. Businesses should conduct thorough audits of supplier manufacturing facilities. They verify production capabilities, testing protocols, and quality control measures. Suppliers must demonstrate their ability to provide detailed documentation. This documentation proves component performance and traceability. Establishing clear communication channels with suppliers becomes crucial. This ensures they understand the new technical requirements and compliance expectations. A robust qualification process minimizes risks associated with non-compliant parts entering the supply chain.

Supply Chain Resilience: Mitigating Disruption Risks

The transition to new TPMS standards introduces potential supply chain vulnerabilities. Businesses must proactively build resilience into their sourcing strategies. Diversifying the supplier base helps mitigate risks. Relying on a single supplier for critical components can lead to significant disruptions if that supplier faces compliance issues or production delays. Companies should also consider dual-sourcing strategies for essential parts. This ensures continuity of supply. Establishing strong relationships with multiple qualified suppliers provides flexibility. It allows businesses to adapt quickly to unforeseen challenges. Furthermore, maintaining adequate buffer stock for key components can prevent production halts. This strategic inventory management supports uninterrupted manufacturing during the transition period. Proactive planning and robust supplier networks are vital for navigating these changes successfully.

Proactive B-to-B Sourcing Strategies for 2025 Regulatory Compliance

Early Engagement with Suppliers: Collaborative Compliance

Businesses gain significant advantages by engaging suppliers early in the compliance process. This proactive approach fosters a collaborative environment. Companies should share their understanding of the 2025 TPMS Regulations with key suppliers. This ensures everyone understands the new requirements. Early discussions allow suppliers to adapt their product roadmaps and manufacturing processes. They can then align these with upcoming technical specifications. Joint planning sessions help identify potential challenges and solutions before they become critical. This collaboration can involve sharing design specifications, testing protocols, and implementation timelines. Suppliers can offer valuable insights into new technologies or materials. Their expertise can streamline the transition. Establishing clear communication channels from the outset minimizes misunderstandings. It also accelerates the development of compliant components. This partnership approach builds stronger, more reliable supply chains.

Technology Adoption and Innovation: Leveraging Advanced TPMS Solutions

Embracing new technologies offers a strategic advantage for meeting the 2025 TPMS standards. Companies should explore advanced TPMS solutions beyond basic pressure monitoring. This includes sensors with enhanced accuracy and longer battery life. Innovations in wireless communication protocols can improve data transmission reliability. Integrated systems that provide predictive maintenance insights also offer value. These systems can alert drivers to potential tire issues before they become critical. Businesses should evaluate suppliers offering cutting-edge TPMS technologies. This includes solutions leveraging IoT connectivity and data analytics. Such technologies provide real-time performance monitoring and diagnostic capabilities. Investing in these advanced solutions ensures not only compliance but also superior product performance. It positions companies as leaders in vehicle safety and technology.

Contractual Safeguards: Legal Protections in Sourcing Agreements

Robust contractual agreements are essential for managing compliance risks with B-to-B suppliers. Companies must update their sourcing contracts to reflect the 2025 TPMS requirements. These agreements should include specific clauses detailing component specifications and performance standards. They must also outline testing and validation procedures. Key contractual elements include:

- Compliance Guarantees: Suppliers must explicitly guarantee their components meet all applicable TPMS regulations.

- Indemnification Clauses: These protect the buyer from liabilities arising from supplier non-compliance.

- Audit Rights: Buyers should retain the right to audit supplier facilities and quality control processes.

- Service Level Agreements (SLAs): These define performance metrics, delivery schedules, and quality benchmarks.

Tip: Clearly define penalties for non-compliance within contracts. This incentivizes suppliers to maintain high standards and adhere to all regulatory mandates.

These legal protections provide a framework for accountability. They mitigate financial and reputational risks associated with non-compliant parts.

Internal Readiness: Cross-Functional Alignment for Sourcing Success

Achieving Regulatory Compliance requires a coordinated effort across various internal departments. Sourcing teams cannot operate in isolation. They must collaborate closely with engineering, legal, quality assurance, and product development teams. Engineering provides technical specifications and validation criteria. Legal ensures contracts contain necessary safeguards. Quality assurance establishes testing protocols and monitors supplier performance. Product development integrates compliant components into final products. Regular cross-functional meetings facilitate information sharing and decision-making. Training programs can educate employees on the new TPMS regulations and their implications. Establishing clear internal communication channels ensures everyone understands their role in the compliance process. This holistic approach ensures a smooth transition and successful integration of new TPMS requirements.

Proactive adaptation to the 2025 US TPMS changes is crucial. Strategic B-to-B sourcing goes beyond mere Regulatory Compliance. It actively safeguards business continuity. This approach also enhances product quality. Companies maintain their market leadership in a rapidly evolving landscape.

FAQ

What are the primary changes in the 2025 US TPMS regulations?

The 2025 regulations demand stricter accuracy, improved reliability across conditions, and expanded coverage for more vehicle types. Manufacturers must meet elevated technical specifications.

How do these new regulations impact supplier qualification?

Businesses must implement more rigorous vetting processes. They need to audit supplier facilities and verify quality management systems. Suppliers must demonstrate consistent compliance and provide detailed documentation.

What are the main consequences of non-compliance with the 2025 TPMS rules?

Non-compliance can lead to significant financial penalties from NHTSA. Companies also risk mandatory product recalls. This severely damages brand reputation and erodes consumer trust.

Post time: Oct-24-2025