You can effectively evaluate a TPMS kit supplier’s inventory. Systematically analyze its breadth and depth using specific, quantifiable metrics. This approach helps you meet customer demand and minimize stockouts. You also optimize your own inventory investment, enhancing your overall Inventory Management, Supply Chain. Strong Inventory Management,Supply Chain practices are essential.

Key Takeaways

- Evaluate a TPMS kit supplier’s inventory breadth. This means checking how many different vehicles and sensor types their kits support. A wide range helps you serve more customers.

- Assess a supplier’s inventory depth. This involves looking at their order fulfillment rate and how much stock they keep. Good depth ensures you get products on time and avoid running out.

- Look at how a supplier manages their inventory and communicates. They should use good systems and be open about stock levels. This helps you make smart buying choices and keep your customers happy.

Assessing Inventory Breadth for Diverse Market Needs

You must understand a TPMS kit supplier’s inventory breadth. This helps you meet the varied demands of your customer base. A broad inventory ensures you can serve many vehicle types and technology requirements.

Vehicle Coverage Percentage

You should evaluate a supplier’s vehicle coverage percentage. This metric shows the proportion of vehicle makes, models, and years their TPMS kits support. A high percentage means the supplier offers solutions for most vehicles on the road. This reduces your need to source from multiple vendors. You can ask for a detailed compatibility list or a database access. This allows you to verify their claims.

Tip: Aim for suppliers who cover at least 90% of the active vehicle parc in your target market. This minimizes gaps in your offerings.

Sensor Technology Variety

TPMS sensors use different technologies. You will find both direct and indirect systems. Direct systems use sensors inside each tire. Indirect systems use the vehicle’s ABS system. Within direct systems, you encounter various sensor types. These include programmable, pre-programmed, and universal sensors. A good supplier offers a wide range of these technologies. This ensures you can meet specific vehicle requirements. It also caters to different customer preferences for installation and cost.

- Programmable Sensors: You can program these sensors to fit many vehicles.

- Pre-programmed Sensors: These sensors come ready for specific vehicle applications.

- Universal Sensors: These sensors offer broad compatibility with fewer part numbers.

Kit Component Inclusivity

A TPMS kit often includes more than just the sensor. You should check if the supplier’s kits are comprehensive. A complete kit might include valve stems, nuts, caps, and even service kits. These service kits contain seals and washers. Supplying complete kits simplifies your purchasing process. It also ensures your customers have all necessary parts for a proper installation. Incomplete kits lead to extra ordering and potential delays.

New Product Introduction Rate

The automotive market constantly evolves. New vehicle models come out regularly. These new models often require new TPMS sensor designs or technologies. You need a supplier who actively introduces new products. This rate shows their commitment to staying current. It also indicates their ability to support the latest vehicles. Ask about their research and development efforts. Inquire about their timeline for releasing new TPMS solutions. A consistent new product introduction rate keeps your inventory relevant and competitive.

Note: A supplier with a strong NPI rate helps you avoid obsolescence. It also ensures you can service newer vehicles quickly.

Ensuring Availability with Inventory Depth Metrics

You must also assess a TPMS kit supplier’s inventory depth. This ensures consistent product availability. It helps you meet customer demand without interruption. Depth metrics reveal the supplier’s ability to maintain sufficient stock levels.

Order Fulfillment Rate

You should examine a supplier’s order fulfillment rate. This metric shows the percentage of orders they ship completely and on time. A high fulfillment rate means the supplier consistently delivers what you order, when you expect it. This directly impacts your ability to serve your customers. You can request historical data from potential suppliers. Look for rates consistently above 98%. A lower rate suggests potential delays and stockouts for your business.

Tip: A supplier with a strong order fulfillment rate helps you maintain your own delivery promises.

Average Days of Supply per SKU

You need to understand the average days of supply for each SKU. This metric tells you how many days a specific product can last. It bases this calculation on current inventory levels and historical sales data. A healthy days of supply indicates the supplier holds enough stock. This buffer helps them handle unexpected demand spikes. You should ask for this data. It helps you gauge their readiness. Too few days of supply means higher risk of stockouts. Too many days might suggest slow-moving inventory.

Backorder Frequency and Resolution

You must evaluate a supplier’s backorder frequency. A backorder occurs when an item is out of stock but still ordered. High backorder frequency signals poor inventory planning. It can lead to significant delays for your customers. You also need to assess their backorder resolution process. How quickly do they fulfill backordered items? Do they communicate clearly about expected delivery dates? A supplier with low backorder rates and efficient resolution procedures minimizes disruption to your operations.

Supplier Inventory Turnover Ratio

You should analyze the supplier’s inventory turnover ratio. This ratio measures how many times a supplier sells and replaces its entire inventory over a specific period. A high turnover ratio often indicates efficient Inventory Management, Supply Chain practices. It means the supplier moves products quickly. This reduces the risk of holding outdated or obsolete stock. A low turnover ratio might suggest slow-moving inventory or poor demand forecasting. You can request this ratio and compare it to industry benchmarks. A healthy turnover ensures you receive fresh, relevant products.

Strategic Inventory Management: Qualitative Supplier Evaluation

You must look beyond numbers when evaluating a TPMS kit supplier. Qualitative factors reveal their operational strength. These factors show their commitment to your success.

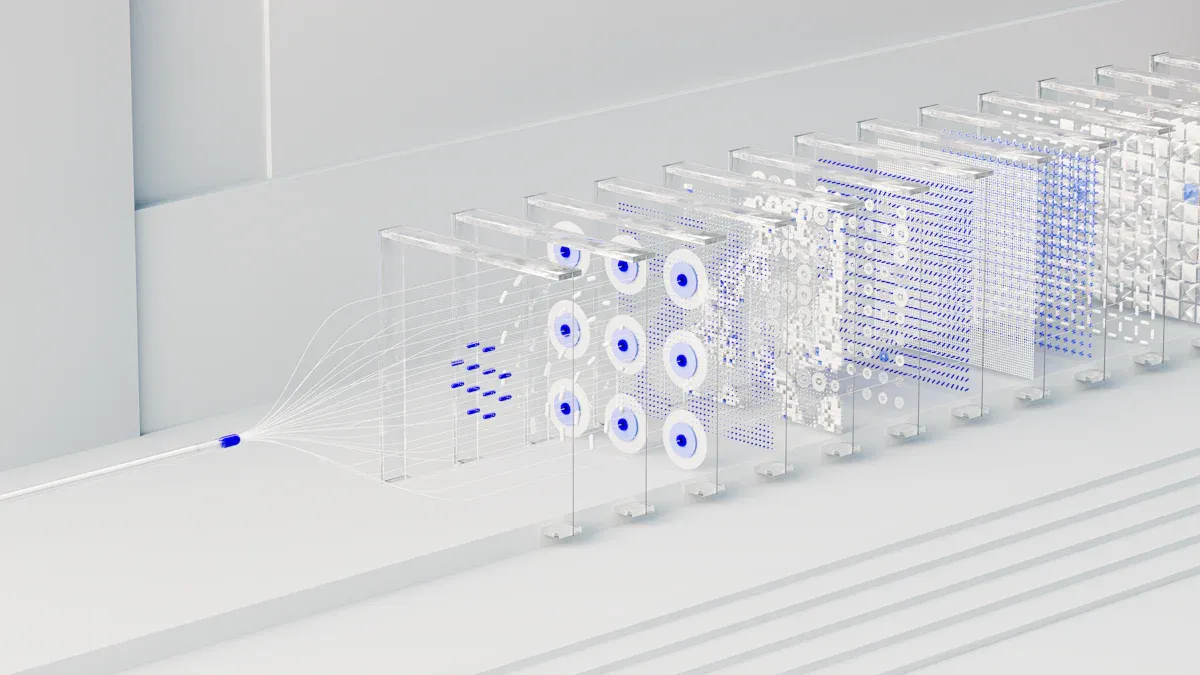

Supplier’s Inventory Management Systems

You should investigate the supplier’s internal Inventory Management, Supply Chain systems. Do they use modern software? Do they employ robust forecasting methods? An advanced system helps them predict demand accurately. It also ensures efficient stock rotation. This reduces the risk of obsolete parts. A well-managed system means fewer stockouts for you. It also means more reliable deliveries.

Real-time Stock Level Transparency

You need clear visibility into a supplier’s inventory. Can you access real-time stock levels? Many top suppliers offer online portals or API integrations. This transparency allows you to make informed purchasing decisions. You can check availability before placing an order. This prevents unexpected delays. It also helps you manage your own customer expectations.

Returns and Warranty Process Efficiency

You must also consider the supplier’s returns and warranty process. Is it straightforward and efficient? A clear policy and quick resolution are vital. This minimizes downtime for your customers. It also reduces administrative burdens for your team. An efficient process reflects a supplier’s commitment to quality and customer service. It builds trust in your partnership.

Optimizing the Supply Chain: Continuous Supplier Performance Monitoring

You must continuously monitor your TPMS kit supplier’s performance. This ensures your supply chain remains efficient and responsive. Regular evaluation helps you maintain optimal Inventory Management, Supply Chain practices.

Key Performance Indicators (KPIs) for Supplier Evaluation

You should establish clear Key Performance Indicators (KPIs) for your suppliers. These metrics help you track their effectiveness. Important KPIs include on-time delivery rates, order accuracy, and product quality. You also monitor their responsiveness to inquiries. Regularly review these KPIs. This identifies areas for improvement. It also ensures your supplier consistently meets your expectations.

Communication Protocols for Inventory Updates

You need robust communication protocols with your supplier. Establish clear channels for inventory updates. This includes regular stock level reports and alerts for potential shortages. Discuss upcoming product changes or discontinuations. Effective communication prevents surprises. It allows you to adjust your own inventory plans proactively.

Adaptability to Market Changes and Demand Fluctuations

Your supplier must show adaptability. The market for TPMS kits can change quickly. New vehicle models emerge. Demand can fluctuate due to seasonal trends or economic shifts. Evaluate how quickly your supplier adjusts to these changes. Do they offer flexible ordering options? Can they scale production up or down as needed? A flexible supplier helps you navigate market volatility successfully.

You diligently apply these breadth and depth metrics. You also consider qualitative factors and continuous monitoring. This helps you make informed decisions about TPMS kit suppliers. You ensure optimal inventory and reduce stockouts. This enhances customer satisfaction and strengthens your Inventory Management, Supply Chain.

FAQ

How does vehicle coverage percentage help me?

This metric shows how many vehicle types a supplier’s kits support. A high percentage means you can serve more customers with fewer suppliers.

Why is sensor technology variety important?

Different vehicles need different sensor types. A varied offering ensures you meet specific technical requirements and customer preferences.

What does a high order fulfillment rate mean for my business?

A high rate means your supplier consistently delivers complete orders on time. This helps you keep your own promises to customers.

Post time: Oct-31-2025