Ensuring vehicle connection integrity requires careful design and manufacturing. Fundamental strategies involve precise thread engineering and effective torque retention. These elements directly contribute to vehicle reliability and driving Precision, Safety. Therefore, proper thread precision and torque retention are essential for overall vehicle Precision,Safety.

Key Takeaways

- Precise threads make sure fasteners fit together perfectly. This creates a strong hold and stops parts from coming loose.

- Torque retention keeps fasteners tight over time. This prevents vehicle parts from separating, even with vibrations.

- Good thread precision and torque retention are very important for driving safety. They help keep your car stable and prevent accidents.

The Unseen Threat of Fastener Loosening

Why Fasteners Lose Their Grip

Fasteners, though small, face constant challenges. Vibration is a primary culprit. Vehicle movement creates continuous shaking. This shaking gradually works fasteners loose. Thermal expansion and contraction also contribute. Materials expand when hot and shrink when cold. This repeated movement can reduce clamping force. Improper installation torque is another significant factor. Too little torque means the fastener lacks sufficient tension. Too much torque can damage threads, weakening the connection. Corrosion can also degrade fasteners or the surrounding material. Dynamic loads from bumps or sudden braking apply stress. These forces cause fasteners to fatigue over time, leading to loosening.

The Critical Dangers of Compromised Connections

A loose fastener poses serious risks. It can lead to component separation. For example, a wheel could detach from an axle. This directly impacts vehicle stability and control. Drivers may lose the ability to steer or brake effectively. Braking systems rely on secure connections; loose parts compromise stopping power. Steering components must remain tight for precise control. A loose steering rod creates dangerous play. Engine mounts prevent excessive engine movement. Their failure causes severe damage and potential loss of power. Ultimately, compromised connections significantly increase the risk of accidents. They endanger vehicle occupants and other road users.

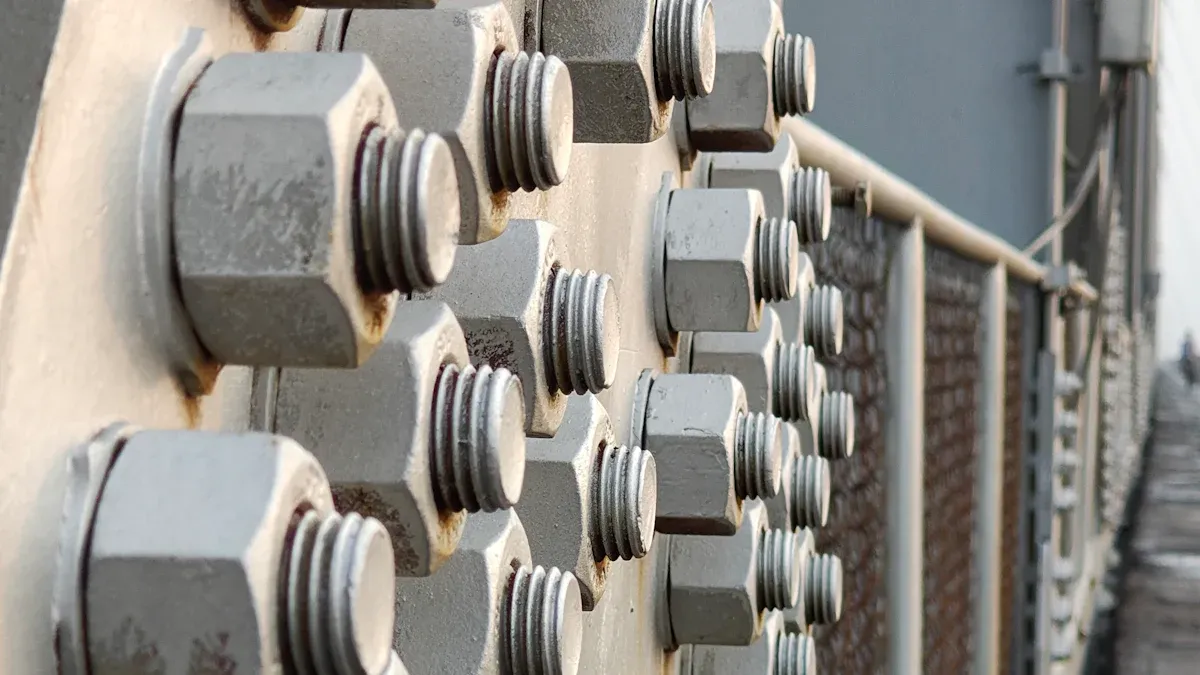

Thread Precision: The Foundation of Secure Fastening

Defining Thread Accuracy and Quality

Thread accuracy refers to how closely a fastener’s threads match its intended design specifications. This includes precise measurements for thread pitch, diameter, and angle. High-quality threads show smooth surfaces and consistent profiles. They have no burrs, nicks, or other defects. Manufacturing processes play a big role in achieving this accuracy. Advanced machining and strict quality control ensure threads meet exact standards. When threads are accurate, they fit together perfectly. This perfect fit is essential for a strong connection.

How Precision Enhances Clamping Force

Precise threads allow for full and even engagement between the bolt and nut. This means the threads distribute the load uniformly across their surfaces. When threads are not precise, they may only touch at a few points. This creates stress concentrations. Even engagement reduces friction during tightening. Less friction means more of the applied torque converts into actual clamping force. A higher, more consistent clamping force holds components together more securely. This strong clamp resists forces that try to loosen the fastener.

Minimizing Play for Lasting Stability

“Play” refers to any small gaps or looseness between mating threads. Imperfect threads can create these tiny spaces. When a fastener has play, it can move slightly under vibration or dynamic loads. This movement can quickly lead to loosening. Precise threads minimize these gaps. They create a tight, intimate fit between the bolt and nut. With less play, the connection remains stable. This stability helps the fastener maintain its clamping force over time. It ensures lasting integrity, contributing to overall vehicle Precision, Safety.

Torque Retention: Maintaining the Critical Clamp

Even with perfect threads, fasteners can still loosen. Torque retention ensures the connection stays tight. It means the fastener keeps its clamping force over time. This prevents parts from separating. Various methods help fasteners maintain their grip.

Mechanical Locking Mechanisms for Durability

Mechanical locking mechanisms physically prevent fasteners from rotating loose. These devices add friction or create a positive lock.

- Lock Washers: These washers create tension. They flatten when tightened. This tension resists loosening from vibration. Some lock washers have teeth that bite into the fastener and the joint surface. This biting action stops rotation.

- Nyloc Nuts: A Nyloc nut has a nylon insert. The bolt threads cut into this nylon. This creates friction. The friction holds the nut in place. It resists vibration and shock.

- Castle Nuts and Cotter Pins: A castle nut has slots on its top. A hole goes through the bolt. You insert a cotter pin through the nut’s slot and the bolt’s hole. The cotter pin physically stops the nut from turning. This provides a very secure lock.

- Tab Washers: These washers have tabs. You bend the tabs against the nut or bolt head. This prevents the fastener from rotating.

These mechanical solutions offer reliable ways to keep fasteners tight. They are often visible and easy to inspect.

Chemical Solutions for Enhanced Grip

Chemical solutions add strength to threaded connections. They fill gaps and harden. This prevents movement.

- Threadlockers: These are liquid adhesives. You apply them to the threads before assembly. The liquid hardens when it is away from air and in contact with metal. This creates a strong bond.

- Low Strength: These are for small screws. You can remove them with hand tools.

- Medium Strength: These work for most common fasteners. You can remove them with hand tools, sometimes with more effort.

- High Strength: These create a permanent bond. You often need heat to remove them.

- Sealants: Some chemical compounds act as both threadlockers and sealants. They prevent leaks while also securing the fastener. They are common in fluid systems.

Chemical solutions fill microscopic gaps between threads. This eliminates play. They also increase the friction needed to loosen the fastener. This makes the connection much more resistant to vibration and shock.

Design Innovations for Sustained Retention

Modern engineering introduces new fastener designs. These designs inherently resist loosening. They improve torque retention from the start.

- Prevailing Torque Fasteners: These fasteners create friction even before full tightening. They have features like distorted threads or non-metallic inserts. This built-in friction helps them resist loosening.

- Self-Locking Bolts and Nuts: Some designs use unique thread forms. These forms create an interference fit. The threads wedge against each other. This wedging action prevents rotation.

- Flanged Fasteners: These fasteners have a wider base, or flange. The flange increases the bearing surface area. This distributes the load better. It also helps prevent embedding into the material. This maintains clamping force.

- Vibration-Resistant Designs: Engineers design some fasteners specifically for high-vibration environments. They might have unique thread profiles or integrated locking features. These features actively counteract loosening forces.

These design innovations build torque retention directly into the fastener. They offer long-term security. They reduce the need for additional locking components. This simplifies assembly and improves reliability.

Precision, Safety: Direct Impact on Driving Integrity

Preventing Component Separation on the Road

Secure fasteners prevent critical parts from detaching. Wheels, for instance, rely on tightly torqued lug nuts. If these nuts loosen, a wheel can separate from the vehicle. This creates an immediate and severe hazard. Suspension components also need secure connections. A loose ball joint or control arm bolt can cause the suspension to fail. This directly impacts the vehicle’s ability to stay on the road. Engine mounts keep the engine firmly in place. Their failure leads to engine displacement and potential damage. Proper thread precision and torque retention are vital. They ensure every component remains exactly where it belongs. This directly contributes to overall Precision, Safety.

Ensuring Vehicle Stability and Control

Vehicle stability depends on every connection remaining firm. Steering systems require precise and secure fasteners. Loose bolts in the steering linkage cause excessive play. This makes the vehicle difficult to control. Braking systems also demand absolute integrity. Calipers and brake lines must stay tightly attached. A loose brake component compromises stopping power. Suspension systems absorb road shocks. They keep tires in contact with the road. Fastener failures in these systems lead to unpredictable handling. Drivers lose confidence and control. Maintaining these connections ensures predictable vehicle behavior. This is crucial for driver and passenger Precision, Safety.

Real-World Consequences of Fastener Failure

Fastener failures have serious real-world consequences. A wheel detaching at highway speeds can cause a catastrophic accident. This endangers the vehicle’s occupants and others nearby. Loose steering components can lead to a loss of directional control. The driver cannot steer the vehicle effectively. This often results in collisions. Brake system failures mean the vehicle cannot stop. This creates unavoidable impacts. These incidents cause severe injuries, fatalities, and extensive property damage. The integrity of every fastener directly impacts human lives. Therefore, meticulous attention to thread precision and torque retention is not just good practice. It is a fundamental requirement for driving Precision, Safety.

Best Practices for Optimal Fastener Performance

Manufacturing Standards and Quality Assurance

High-quality fasteners begin with strict manufacturing standards. Manufacturers follow international guidelines like ISO and ASTM. These standards ensure consistent thread precision and material strength. Quality assurance processes involve rigorous testing. Technicians inspect fasteners for defects, dimensions, and material composition. They perform tensile strength tests and fatigue tests. This careful oversight guarantees each fastener meets performance requirements. It prevents weak or faulty parts from reaching vehicles.

Essential Maintenance and Inspection Protocols

Regular maintenance helps fasteners perform their best. Vehicle owners should follow manufacturer inspection schedules. Technicians perform visual checks for corrosion or damage. They also verify proper torque settings. Loose fasteners require immediate tightening to the correct specification. Damaged fasteners must be replaced. Ignoring these protocols can lead to unexpected failures. Proactive maintenance ensures all connections remain secure.

Selecting the Right Fasteners for the Job

Choosing the correct fastener is crucial for safety. Engineers consider several factors. They match fastener material to the application’s environment. For example, stainless steel resists corrosion in wet conditions. Fastener size and thread type must fit the components perfectly. Coatings can add protection against rust or reduce friction during assembly. Using the wrong fastener can compromise the entire connection. Always select fasteners designed for the specific load and conditions.

Thread precision and torque retention are indispensable for vehicle safety. They prevent fastener loosening, ensuring vehicle integrity. Manufacturers must uphold high standards. Regular maintenance and correct fastener selection are essential. These principles safeguard against operational risks, ensuring every connection contributes to a safer drive and overall Precision, Safety.

FAQ

What makes thread precision important for vehicle safety?

Thread precision ensures a perfect fit between fastener components. This creates a strong, even clamping force. It minimizes gaps, preventing loosening from vibration.

What does torque retention mean for a vehicle’s connections?

Torque retention means a fastener keeps its clamping force over time. It prevents loosening from vibrations and dynamic loads. Mechanical and chemical methods help maintain this grip.

How do fasteners directly impact driving safety?

Secure fasteners prevent critical vehicle parts from separating. They ensure stability and control. Loose fasteners can cause accidents, leading to injuries or fatalities.

Post time: Nov-12-2025