1. Production Background

For the extra heavy oil in Xiaowa Oilfield, the pumping unit that is used is used for mining. For upward impulse, the head suspension point needs to lift the oil rod. When the suction machine goes down the column, the liquid column is not allowed to go up when the pump is pumping, so that the condition of the donkey head changes. In the downstroke, the locomotive plays a role under the action of its own weight, plays a role in the working process, lets it play its role, plays its role, plays its role, plays a role under the action of the tanker's own weight, plays a role in the working process, and Not play a role in tankers, not balance. Manual work in the pumping process does not distinguish the unbalance of the pumping unit.

2. Hazards of Unbalanced Pumping Unit

When the wheel weights is unbalanced, it will bring the following hazards:

(1) Reduce the efficiency and life of the motor. Due to the uneven load, the electric motor bears a great load in the up stroke, and the pumping unit runs with the electric motor in the down stroke, resulting in a waste of power and reducing the efficiency and life of the electric motor.

(2) Shorten the service life of the pumping unit. Due to the uneven load, the load is suddenly large and small during one revolution of the crank, which will cause the pumping unit to vibrate violently and shorten the life of the pumping unit.

(3) Affect the normal operation of the pumping unit and pump. Due to the uneven load, the uniformity of the rotation speed of the crank will be destroyed, so that the head of the donkey will not swing evenly up and down, which will affect the normal operation of the pumping unit and the pump.

For this reason, due to the problems caused by the unbalance of the pumping unit, the adjustment and balance of the pumping unit has become a more frequent task in the daily production work of the oil production operation area. Each oil well needs to be adjusted and balanced once or twice a year. According to statistics, in 2015, the average number of balancing adjustments per month in the operating area reached 15 to 20 well times. According to the current situation of balancing adjustment, it requires a long shutdown time, which has a great impact on heavy oil wells, which is easy to cause liquid drop and outflow. , stuck wells, etc. Therefore, it is urgent to develop a device that can shorten the time for balancing the pumping unit.

3. Solution

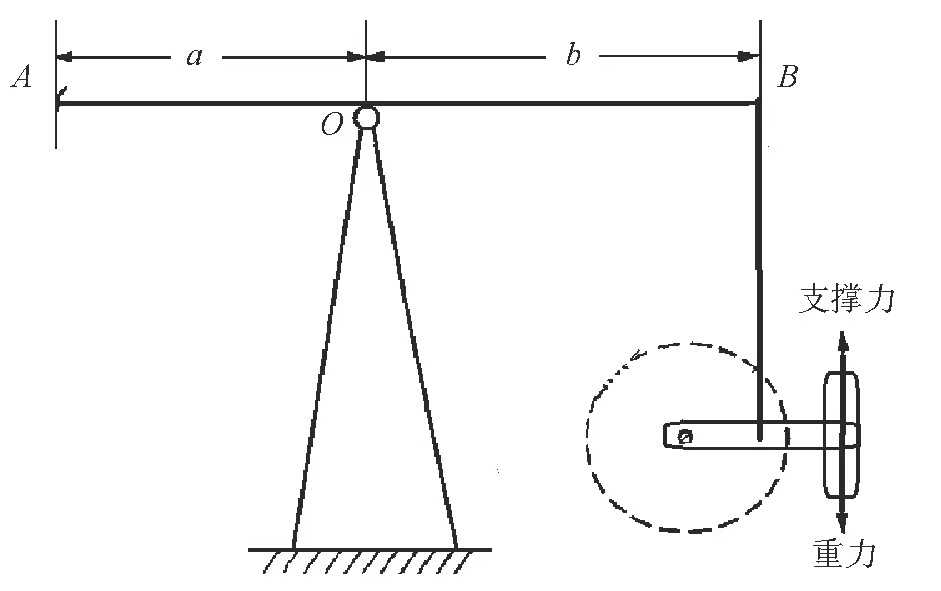

At present, adjusting the balance weight of the pumping unit is to adjust the crank to the horizontal position with the brake, and use the tool to move the balance weight to the designated position (Figure 1). The horizontal position of the crank is chosen because the vertical direction of the balance weight is only affected by the weight of the balance weight and the supporting force of the crank to the balance weight. There is no force in the horizontal direction, and it is in a static state. At this time, the external force is used to push the balance block to the designated position, which is the most labor-saving.

Considering the position of the crank of the pumping unit, only the horizontal position and the lateral position can be selected to adjust the operation position of the balance weight. After comparative analysis (Table 2), it is determined that the operating device adopts the horizontal position. After the fixing position is determined as the crank plane, the fixing method is analyzed. Through the understanding of the fixing methods on the market and the actual situation of the crank, it is known that the fixing method of the mobile device can only choose the threaded connection and the clamp connection. After investigation and discussion, the advantages and disadvantages of the fixed method were compared and analyzed (Table 4). After the comparison and analysis of the schemes is completed, the final fixing method is selected as threaded connection. After selecting the operating position of the mobile device as the horizontal position, and selecting the fixed position as the crank plane, it is necessary to select the contact surface between the mobile device and the balance weight. Due to the characteristics of the balance block itself, the side of the balance block is the contact surface, and the mobile device can only be in point-to-surface, surface-to-surface contact.

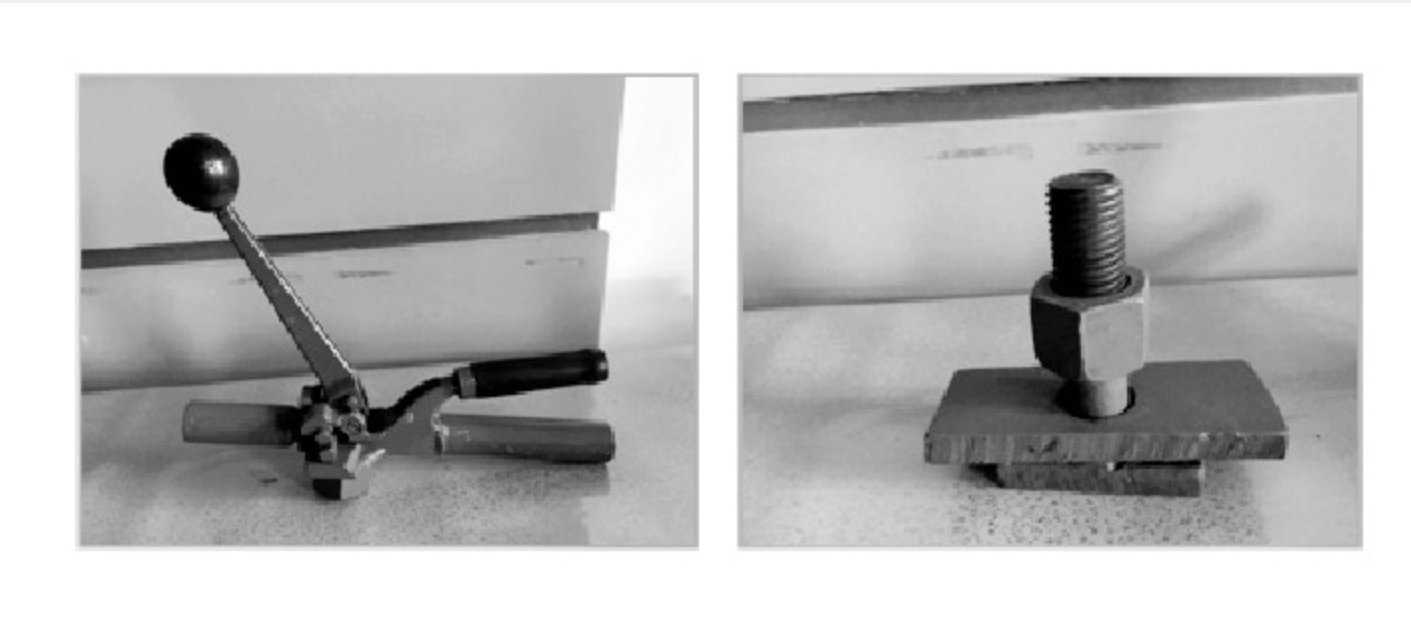

4. Integration of Components

The components of the mobile device and their integration effects are shown in the figure below.

The adhesive weights, the repeated up and down movement is transformed into the counterclockwise rotation of the transmission gear, and the main tooth and auxiliary tooth lock pin limit, drive the tooth belt to extend, so as to achieve the purpose of "expanding and tightening" (Figure 3). In September 2016, the balance adjustment operation experiment was carried out on Well 2115C and Well 2419 of Wa Shiba Station. The installation test for adjusting the position of the balance block in these two wells took 2 minutes and 2.5 minutes respectively (Table 9).

It can be seen from the installation effect of the two wells (Fig. 4) that the device fully meets the on-site production requirements, and the adjustment and balance operation is flexible and fast, saving time and effort. The operation area requires in the production management: due to the large changes in the production parameters of the heavy oil well, the pumping unit should be adjusted and balanced in time according to the changes of the load and current. The installation of the device also facilitates the operation of employees and reduces labor intensity. The portable oil pumping unit balance weight mobile device is safe and reliable to use, simple to operate, small in size, light in weight, convenient to carry, has a wide range of applications, and has low manufacturing cost.

After the test was successful, the team carried out promotion and application in the eighth oil production team. From September to October 2016, the balance adjustment operation was carried out in 5 wells, which took an average of 21.5 minutes, and achieved the expected and ideal effect.

5. Conclusion

(1) The device reduces the labor intensity of employees and improves the safety factor of wellhead operation.

(2) Strengthen the maintenance of the pumping unit, discover hidden dangers and eliminate abnormal factors in time, so that the pumping unit can operate under the best working conditions.

(3) The device has the advantages of reasonable design, simple manufacture, reliable operation, convenient on-site operation, low investment and high safety, and is worthy of continuous promotion and application.

Post time: Oct-13-2022