With the development of the automobile industry, the structure, manufacturing technology and performance of tires are continuously improved and improved, and the structure and types of tire valves are also constantly changing and developing. Usually tire valves are divided into two categories: one is the inner tube valve, which is one of the components of the inner tube, which is composed of hexagonal nuts, valve cores, protective caps and other parts. The second is the tubeless valve, which is composed of metal base, valve core and protective cap. In addition, there is also a packaged gourd-shaped tubeless valve that can be directly installed on the rim hole. The tire tube and tubeless tire are inflated, airtight, and deflated through the tire valve, so that the tire can maintain the required pressure under various usage requirements. Among them, the inner tube valve is widely used in the assembly process of our company's wheel assembly. At the same time, there are some problems in the use process.

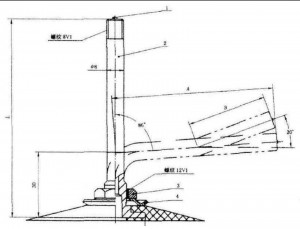

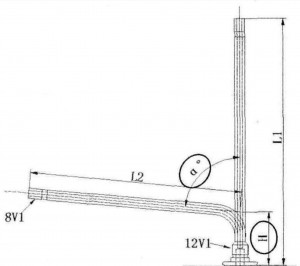

The valve nozzle assembly was installed on the wheel, and the interference was analyzed. The interference between the valve nozzle and the wheel plate and the wheel rim was confirmed. The interference between the valve nozzle and the wheel plate is 4.76mm, the interference between the valve nozzle and the rim is 2.86mm, and the total interference is 7.62mm. Due to the dynamic change of valve nozzle position in the process of inflation, there is a certain difference between theoretical analysis and actual situation.

2.Improvement easure

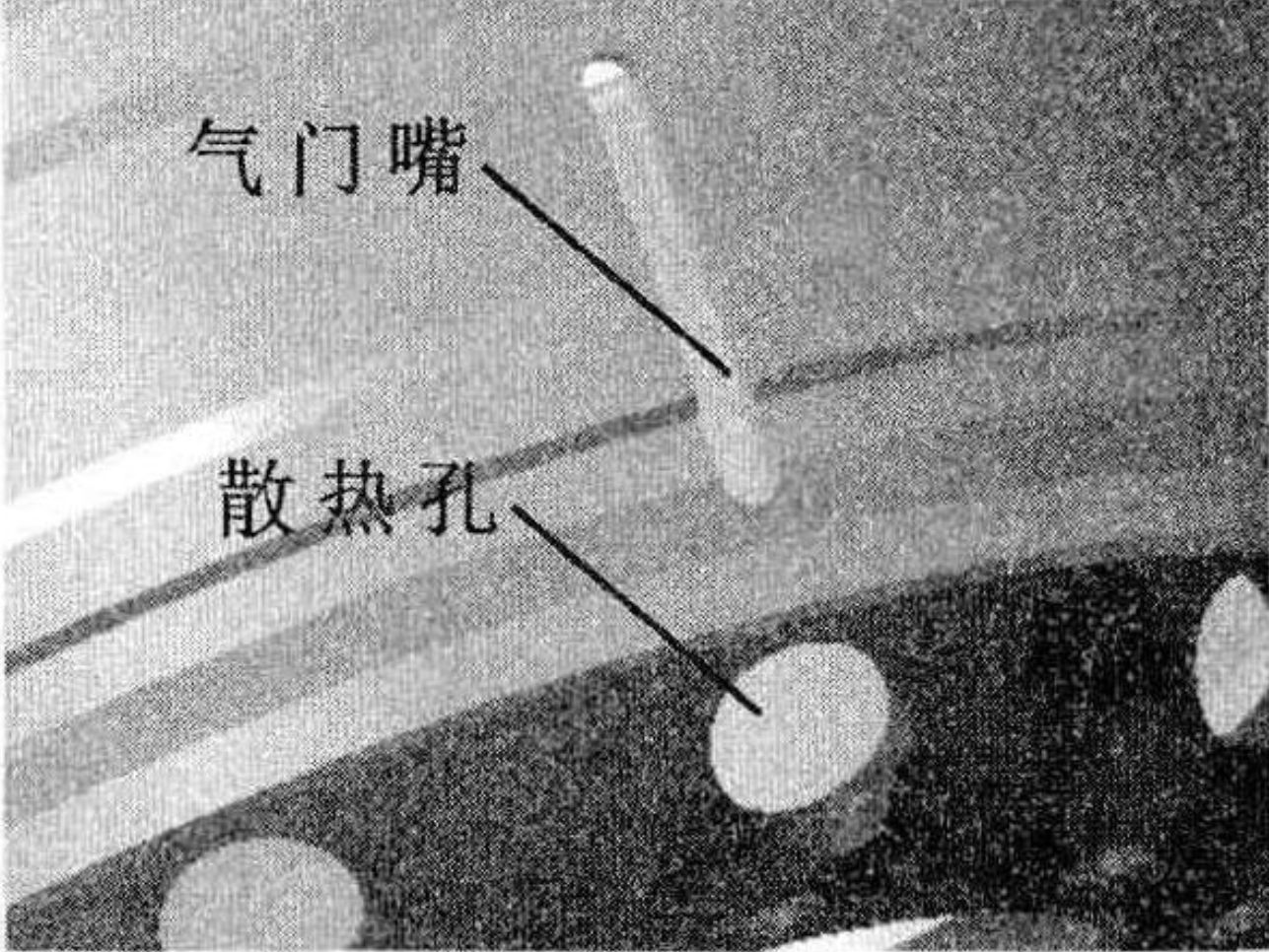

According TO THE ANALYSIS OF THE STRUCTURAL parameters of each part of the valve NOZZles assembly, the improvement of valve nut and gasket ensures that the nut is inserted into the valve noZZles, so that the valve noZZles can obtain a large adjustment range and reduce the interference between the valve nozzles and the rim. At present, some manufacturers use E03C hexagon nuts, stuck phenomenon is widespread. However, changing the valve nut to a non-hexagonal type can avoid stalling.

In summary, it can be seen from the above table that when the bending Angle of the valve nozzle is bent at 84° and the height is 35mm, there is a gap of 3.88mm. However, due to the influence of other hexagon core nuts, D08C inner tube round pads and pad thickness in the pad pad, its height can not be reduced too much. Therefore, the bending Angle of the valve nozzle was bent according to 86°, the height was changed to 35mm, and the valve nut was uniformly changed to non-hexagonal type, which was tested and verified in the field.

3.Improvement Effect

On the basis of not increasing the product cost, not affecting the rim strength and installation, the structure and accessories of the valve nozzle are improved, which completely solves the problem of 8.5-20 rim and valve nozzle interference, improves the production efficiency of tire assembly preassembly, and provides a strong support and guarantee for capacity improvement. At the same time, the problem of inflating after - sale users is solved.

Post time: Aug-12-2022